-40%

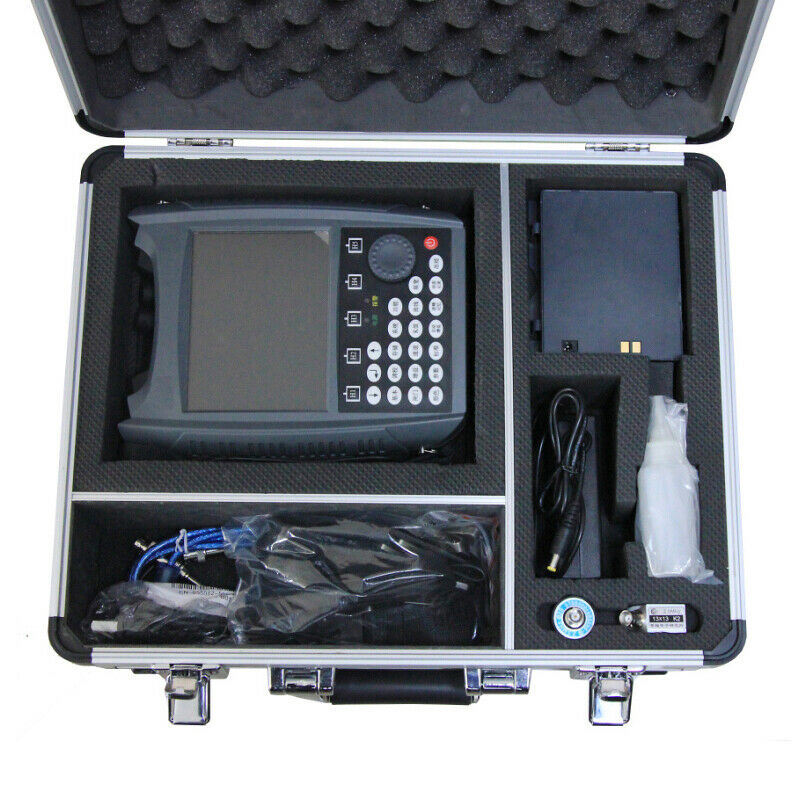

Portable Ultrasonic Flaw Detector NDT Testing with Testing scope 0 to 9999mm

$ 1158.95

- Description

- Size Guide

Description

Portable Ultrasonic Flaw Detector NDT Testing with Testing scope 0 to 9999mmportable ultrasonic default detector series is specially designed for engineering personnel use on nondestructive testing. And its main usage scopes are: testing、 position、evaluation and diagnosis of various destruction。It can easily and accurately conduct nondestructive testing on welding defects, cracks, internal pores of the work piece and other defects. It is widely used on industries such as electrical power project、boiler and pressure vessels、steel structure、military industry、aviation 、railway transportation、automatic machine equipment and so on. it is an indispensable testing tool in the field of nondestructive testing.

Key technical indicators

Item

Indicator

Item

Indicator

Testing scope

0~9999mm

linear inhibition

0~80%(digital suppression)

Working frequency

0.2MHz~15MHz

Vertical linear error

≤3%

Sound velocity

1000m/s~9999m/s

Horizontal linear error

≤0.1%

Gain Coverage

0dB~110dB

Dynamic Scope

≥32dB

Sampling rate

100MHz

Battery

6*3.7V(lithium battery)

Display delay

-20μs~+3400μs

Electricity

8.4V

Probe zero -offset

0μs~99.99μs

Ambient Temperature

-20°C~50°C

Level of electrical noise

≤10%

ambient humidity

20%~90%RH

Surplus sensitivity

>63dB

size

23cm*17cm*5.5cm

Resolution Ratio

>40dB(5P14)

Weight

1.56KGS(including leather case)

Function comparison

Item

SUB100

SUB140

SUB180

SUB200

SUB280

Gate capture

×

×

×

√

√

Number of channels

10

100

100

100

10000

Wave shape

100

1000

1000

1000

10000

Video time

5*10min

60min+50*20min

30h

60h

Color B scanning

×

√

√

√

√

Grayscale scanning

×

×

√

√

√

Eco Encoding

×

Background

Background

waveform

waveform

Calculation aperture

×

√

√

√

√

Welding Picture

×

√

√

√

√

Crackle Detecting

×

√

√

√

√

Thin plate enhancement

×

×

×

×

√

Correction of curved surface

×

√

√

√

√

TCG

×

×

×

√

√

ICAM(English、Chinese)

×

×

×

√

√

Number of Battery

1

2

2

2